The horizontal light may shine in the filers eyes.

Two Light Setup:

Filing Cutter teeth – Lighting and Other Considerations

There is some good information available online about sharpening crosscut saws. This page looks at some methods that I have used with good success. Other crosscut saw filers may find some useful ideas here, or maybe not. It is up to each filer to decide what works best for them.

A most important requirement for filing the cutters is having good light in order to see the filing surface and even more importantly, being able to see the tiny pinpoint of light reflected off the tip of the jointed tooth. There is no way that a filer can get good consistent results without good lighting and good vision.

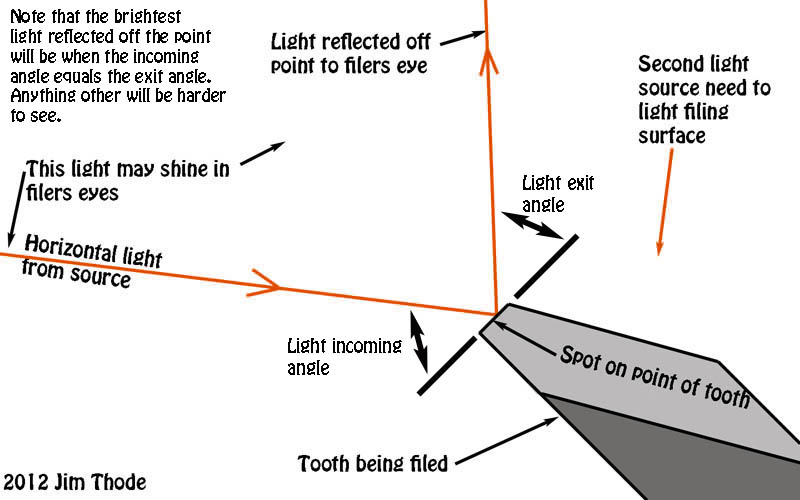

A common lighting method is to have light coming into the saw nearly horizontal toward the filer. With this light source and with the filers eyes in the correct position, the light off the jointed cutter tip will be reflected to the filer’s eyes. In the day, most filing was done with natural light from banks of windows and maybe skylights but today we have the option to use efficient reliable artificial lights.

There is some general information about lighting for filing cutters but no real specific information and what is available does not make sense. For example if a saw is tipped back 45 degrees for filing cutters and the light source is shining in toward the filer at a 45 degree down angle, then the reflection off the tooth points would be directly back at the light source. The filer could see no reflected light and the points would be dull and hard to see.

I see two options available for

lighting;

One is with two lights, one shining nearly horizontal toward the filer’s face and a second light shining down overhead to light up the filed surface of the teeth.

The advantage of the two light setup is that filers have used it for ages. (Maybe that's why you seldom see a very good old vintage sharpening job??)

The disadvantages of the two light setup are:

Two lights are needed

Space is needed for the horizontal light and the vise can’t be put against a wall

The

light will likely be dimmer then a single light system because it is very

difficult to line up your eye in line with the brightest refection

The horizontal light may shine in the filers eyes.

Two Light Setup:

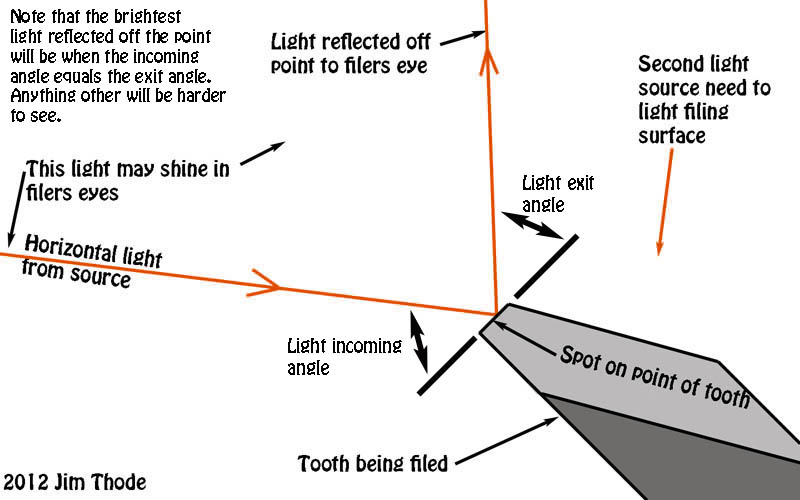

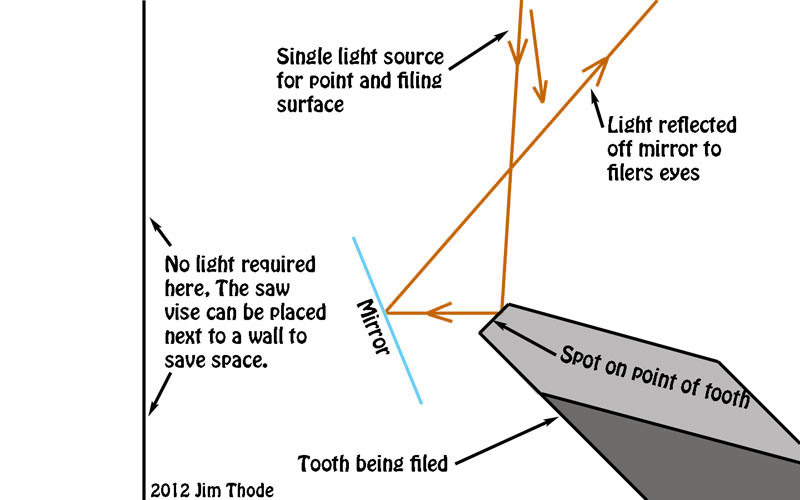

The second option is a good single overhead light source with a small mirror used to see the teeth points.

The advantages of a single light setup

are

Only one light

is needed

The vise can be placed tight against a wall or even

mounted on a wall and that saves space

A portable vise can be placed in any

location with a good single overhead light

The vise can be angled back where it is easiest to file and

not where the light reflection is best, the angle of the mirror controls the

light.

The reflected light will be brighter because of the angles

involved

The disadvantage of the one light setup

is that you have to use a mirror to see the light reflected

off the teeth points.

Single Light with Mirror:

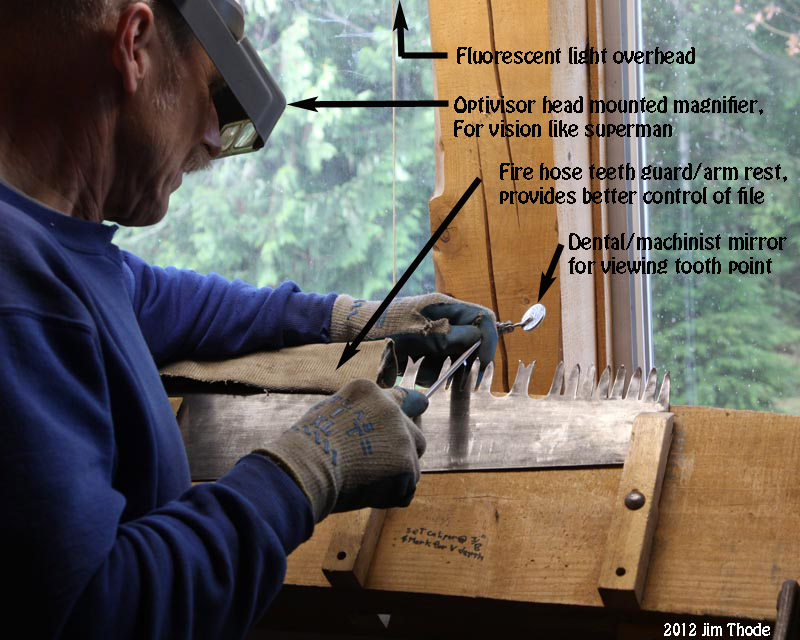

I have always used a single light with a mirror. The

reflection is brighter and I believe that it is possible to get a more

consistent sharpening job. I use a machinist or dental

mirror that I hold in my left hand and it works well. You can pick up dental

mirrors on eBay for less then $5 and the machinist type mirror can be found at

auto parts stores.

I have also used a small makeup mirror but you have to set it

down when filing and pick it up when checking the point.

My vise is normally attached to the wall

in front of a window but I don’t count on the window light for filing.

It just

gives me the ability keep an eye on the homestead during the long hours of

filing.

Some filers have found that a portable light that can be positioned as needed on the back side of the saw works to get good reflections off the teeth points.

Other considerations that I have found useful when filing cutters include:

I use an Optivisor head mounted magnifier. If you can’t see exactly what you are doing, there is no way to get precise consistent results.

I cover the teeth with a section of split fire hose and rest my left arm on the saw. This provides a solid base for my left arm and hand and provides more precise control of the file movement and cutting angle.

I use a gloved thumb (right hand) to push

the burr away to see the point. It is much quicker then removing the filing

burr with a file each time you check for the reflected pinpoint of light on the

tooth point. When the cutter filing is done I remove the bur with a fine

diamond hone.

Comments, suggestions or questions are always welcome.

Jim Thode